RoboGREEN

We love real sustainability. With facts, not just intentions.

We are convinced that economic development can be combined with sustainability through continuous and advanced research. From the choice of raw materials to production, everything in Roboplast is conceived from an eco-design perspective.

Recycling is researching.

This is our path to developing economical and eco-sustainable packaging solutions.

Why PET?

Too precious to be waste.

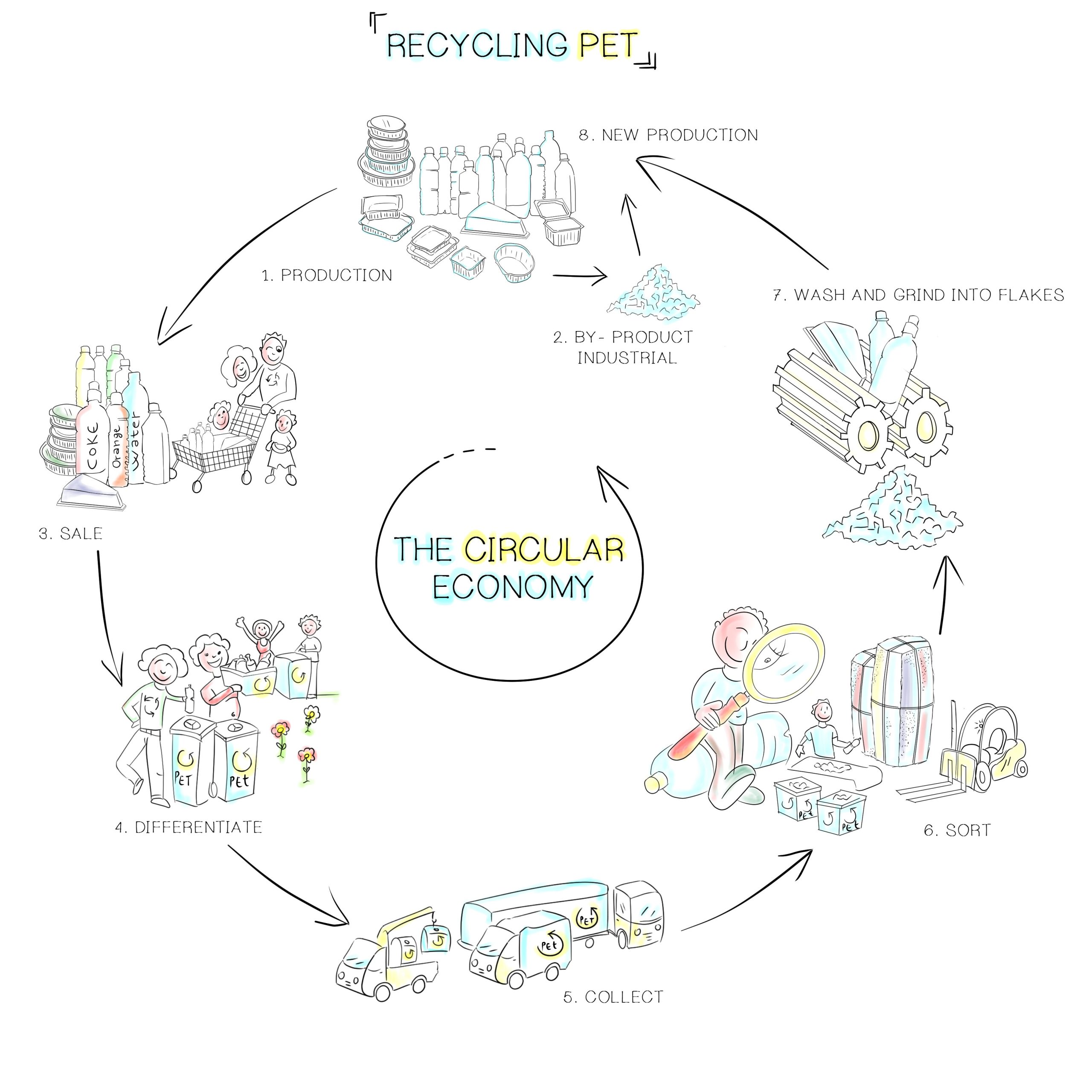

PET (polyethylene terephthalate) is a synthetic material belonging to the polyester family. 100% recyclable, it does not lose its basic properties during the recycling process. It can thus be repeatedly processed to make new products. PET packaging also complies with strict national legislative requirements and international regulations imposed in the food and medical-pharma fields. In a proper circular economy, PET is a valuable resource for everyone.

Roboplast and the search for new materials.

Along with the continuous research on new bioplastics and compostable plastics, in particular to increase their mechanical and oxygen barrier properties, we work to produce high quality innovative products. Take a look at our RoboGREEN materials!

RoboGREEN PET HT

PET HT (high-temperature), up to 100% recycled and 100% recyclable.

RoboGREEN PET HB

PET HB (high-barrier), up to 100% recycled and 100% recyclable.

GLUE LESS™ Technology

Innovative technology for maximum performance with maximum sustainability.

The research

continues…

We haven’t stopped yet. We work every day to find new solutions.

Sustinability Gold Rating

For the fifth consecutive year, Roboplast has received the “gold” medal from Ecovadis, the world’s largest and most trusted provider of corporate sustainability assessments. We are in the top 5% of sustainable plastic manufacturing companies worldwide.

Circular Plastic Alliance

Roboplast is a member of the EU Circular Plastics Alliance, the EU supply chain for healthy and sustainable recycled plastics, which aims to reuse up to 10 million tons of recycled plastics annually to produce new products in Europe by 2025.